NG-IOT For The Next-Generation Supply Chain

By Universitat Politècnica de València

The digitalization of supply chain management is placing firms in the position of competitive advantage, by enhancing how products and services are made and delivered, by attaining higher agilities and, thereby, meeting customer changing needs more efficiently.Among others, supply chain digitalization functionalities include increased information availability through real-time information access, enhanced intra- and inter-company communications, operations and operational efficiency at product design, inventory, and delivery (1) . The main research innovation area that is heavily boosting supply chain digitalization is coming from Internet of Things (IoT). With IoT, former physical computerized objects are also serving as connected nodes, bringing valuable insights to companies and end-users. However, less than 1% of all physical objects are currently connected. While this could be a low penetration rate, supply chain companies are slowly but steadily leveraging the recent advents of IoT to digitalize their management systems. According to DHL (2) , IoT by itself will generate $1.9 trillion worldwide over the next decade in the supply chain ecosystem. In particular, in the world of supply chain, IoT is about sensing, by monitoring different assets within a supply chain through different network technologies and data handling, by managing vast amounts of data generated from sensors, getting valuable insights or new solutions to be exploited.Hence, we consider that we are at the beginning of the IoT period, and the next-generation IoT will need to fully exploit the disruptive advancements that are under standardization in 5G.

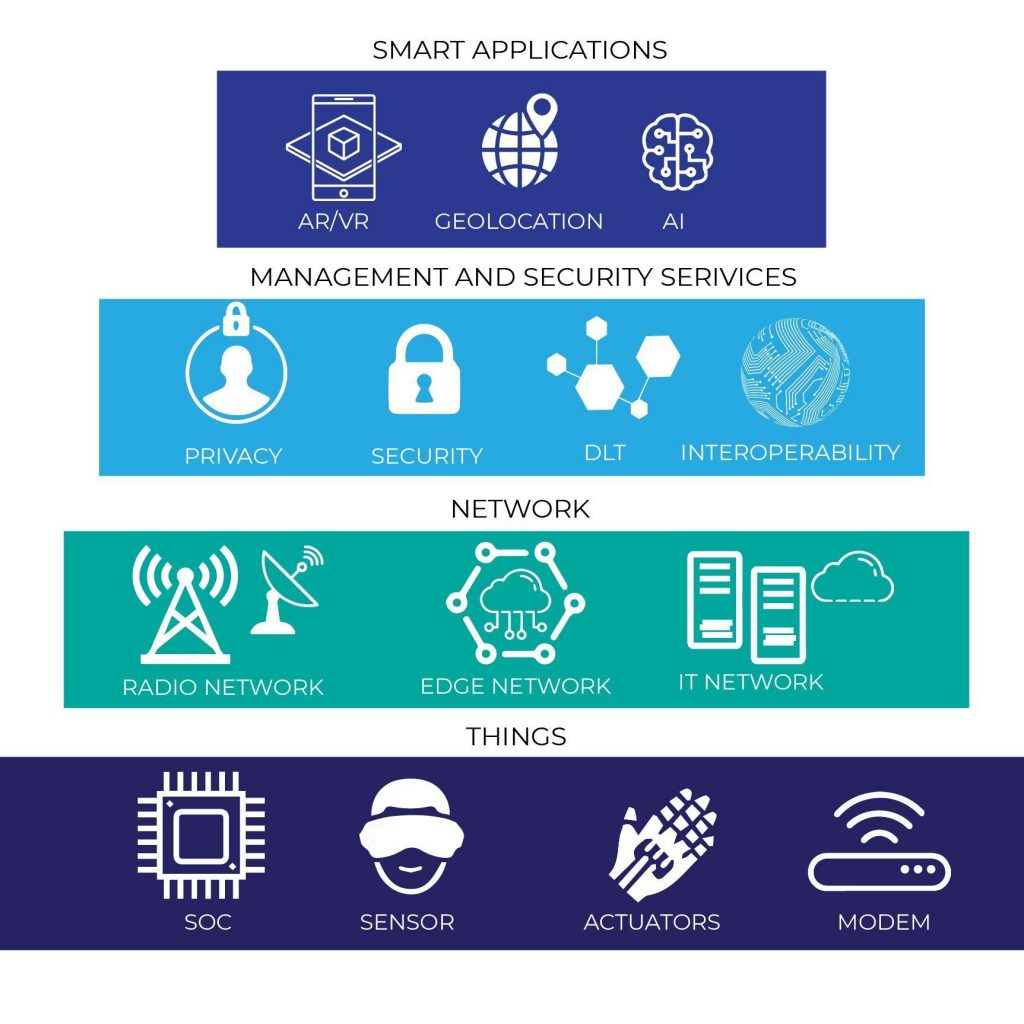

Therefore, we propose to develop a native 5G-IoT solution that will be able to e.g.,provide service operation beyond terrestrial deployments with minimum battery usage, guarantee the ultra-reliable and low- latency communication requirements needed at industrial environments, or enable the use of high-quality video delivery with surveillance cameras.Furthermore, in order to improve data handling and to support highly differentiated demands from several stakeholders in the same physical infrastructure, three key technology enablers such as Edge Computing, Big Data with Artificial Intelligence, and Distributed Ledger Technologies, also known as blockchains, will need to complement the native 5G-IoT solution, as shown in the figure above. On the one hand, IoT devices are expected to produce trillions of gigabytes of data daily. Since all these data will need to be processed with different latency needs, depending on the application purposes, the federated Edge as a Service constitutes a shared resource for delivery of a variety of applications such as automated factories or AR/VR. On the other hand, AI is foreseen as a key enabler for the next-generation IoT, not only to the ever-increasing volumes of data, but also to enhance levels of automation by means of neuromorphic edge sensors and self-organizing network architectures. Finally, a trusted communication along several stakeholders, as well as semantic and syntactic interoperability challenges of heterogeneous cloud platforms in the supply chain market will be available using DLT/blockchain solutions.

SUPPLY CHAIN USE CASES OF iNGENIOUS

The supply chain management process encompasses the planning and control of all activities involved in sourcing, procurement, conversion, production, and logistics management operations (3) . It also comprises the coordination and collaboration with suppliers, intermediaries, third party service providers, and customers. This article will focus on three technological trends addressing the requirements of different activities performed in procurement, operations, and distribution.

Automation is seen as one of the next-generation enablers for supply chain stages, where processes are performed with minimal human assistance. Thanks to its remote and efficient operation, it provides economic benefits for customers and service providers by increasing the productivity, and thus, improving the response time. Additionally, automation techniques can also be exploited to replace human workers in dangerous tasks or for performing risky operations by means of remote controlling objects. The next- generation automation will involve both human and heterogeneous devices with different wireless and wired connection technologies.

These include a variety of localized and distributed environmental, audio, vision and haptic sensors, as well as different types of stationary and mobile actuators, such as switches, robot arms, Automated Guided Vehicles (AVGs), etc.

To manage automatic operations, automation control algorithms may run on localized or distributed controller platforms. Based on the available device, computation and network resources, Application Programming Interfaces (APIs) will be needed for application developers to implement and debug automation applications. High reliability (up to 99.99999%), low latency (below 0.5 ms), and minimal synchronization delays (below 1 s) are key requirements to ensure a safe and efficient operation in environments like factories or ports, where automation and collaborative robotic operations are performed. Furthermore, human sensation and satisfaction also need to be considered for human-in-loop applications to avoid cyber sickness and fatigue

In logistics, goods and inventory items are distributed and transported from warehouses to end-users by using heterogeneous transportation means like trucks, trains, and ships. To collect information about the asset location, carriages status, integrity and security of goods, track-and-trace technologies are considered as key elements within the next-generation supply chain enablers. Multiple logistics environments like factories, retail stores or transport nodes use large amount of IoT sensors and systems to monitor the goods and the operations performed. The analysis of the collected data helps to make the right decisions at the right moment in events like the detection of abnormal situations, route congestion, accidents, and unauthorized access. Track-and-trace allows supply chain players to achieve operational excellence, major reduction in operational uncertainties, and significantly increased revenues. This transparency is a key feature sought for end-to-end visibility with the increase in the business complexity and shipping volumes of the global supply chain. Track-and-trace techniques can be performed by installing various type of sensors on warehouses and transport carriages for measuring temperature, humidity, acceleration, contact, and location. High positioning accuracy and connection density requirements are crucial to ensure an efficient operation while coexisting with many devices in reduced dimensions (up to 4M UEs/km 2 ). Sensors need to be easy to install and operate in autonomous and free-maintenance conditions for more than 12 years. Additionally, wide area connectivity is required to convey the collected data to control centres continuously or on regular-interval basis, along the entire shipping journey, while ensuring security and integrity.

The smart processing and analysis of the big amount of data collected from distributed multimodal IoT sources will enhance the operability and productivity of logistics centres. To enable the interaction between different IoT sources, the interoperability challenge comes from using M2M platforms needs to be addressed. In that sense, the creation of a cross-M2M interoperability layer will

be needed. Once this interoperability is enabled, smartness needs to be introduced. This aspect can be achieved through the development of situational understanding and predictive models that will foresee events and risks to improve certain KPIs. For that purpose, AI/ML technology is seen as a key enabler for: 1) generating models from the combination of different data sources,

2) obtaining useful information from the data models,

3) enhancing the models in semantic processing contexts,

4) developing situational understanding predictive capabilities based on the ingested data.

The authenticity, security, and integrity of data are also crucial for the orchestration of the whole supply chain. In this regard, DLTs are also seen as key enablers to ensure that original documents and events are reported in real-time and made available to authorized actors, providing process transparency and access to original data. The step forward will be represented by each actor using a desired DLT to share and store data in a secured manner. To guarantee a universal and non-segregated realm for DLTs, new ways to interconnect diverse DLTs securely and efficiently will be paramountcy needed.

(1) Z. Seyedghorban, H. Tahernejad, R. Meriton and G. Graham, “Supply chain digitalization: past, present and future”, Production Planning & Control, vol. 31, no. 2-3, pp. 96-114, Dec. 2020

(2) J. Macaulay, L. Buckalew, G. Chung, “Internet of Things in Logistics”, DHL Cust. Solut. Innov., pp 1-27, 2015

(3) Council of Supply Chain Management Professionals (CSCMP), “Supply Chain Management: Terms and Glossary”, Oct. 2013.