NG IoT for Intermodal E2E Asset Tracking

By COSCO SHIPPING Lines (Spain) S.A.

CURRENT SITUATION

It is well known that in the information age in which we live, everyone is moving towards an ever greater digitalization. Logistics cannot be left behind, and within its objectives, the tracking of shipments stands out for being a value increasingly demanded by the customer. In this sense, the customer wants to know the details of the status of his order, where it is, when it will arrive and what is happening with it.

Nowadays, in domestic orders the user is provided with a code to be able to see the status of their shipment, not being tracked in real time, but only the most important events being recorded as crossing between borders, entry and exit of the different warehouses, exit for distribution, delivery to the requested address, etc.

In the transportation of goods, all the agents involved, especially the customer, also wants to receive information about the situation in which their transport is located. To talk about the current situation, we will focus on the transportation of goods by container, since this encompasses most of the transportation of goods excluding dry or liquid bulk goods. We must know the current situation and the advances that are taking place in order to focus on the best action lines. Considering that most of these routes path is by sea, where the connection cannot be as efficient as in the landside, these are the most important events that occur in a container sea transport service:

- Collection in a depot of the empty container and transport to origin for its loading

- Ground transportation to the port, by train, truck or the combination of both

- Arrival and entrance to the port terminal

- Load of the container to the ship and transport by sea

- Possible transshipments to other vessels in other ports

- Arrival at the port of destination and unloading at the terminal

- Collection of the container at the terminal and ground transport by train, truck or the combination of both to the final destination

- Return of the empty container

During this sequence of steps, the container is not geolocated, but it is possible to know its approximate location and estimate its arrival. In inland transport, applications and software that link the geolocation of the truck or the carrier’s phone with the container have been developed, providing this information to the customer.

If there is a section by rail, the departure and arrival of the container can be estimated knowing the schedules of the train and the transit time, but no information on possible changes or unforeseen events can be obtained in real-time.

Terminal entries can be recorded automatically if the port terminal has this process digitized and a Port Community System to access data. Information on entrances and exits of the container depots is sent by corresponding companies via EDI messages.

Once loaded on the ship, the arrival at the final port is estimated in the schedules of the ships. Unfortunately, variations in the schedules of the ships occur in most cases and, in addition, in many cases the container does not travel on the trip as it had been planned. The tracking “in real time” is carried out manually and individually through EDI messages exchanged by the actors involved and different websites on ship’s location. So, port terminal sends the container loading list, the location of the ship can be provided by different websites that give the last known coordinates, note that this information gets available to visualize with a few minutes of delay with respect to reality, updates received from the Captain, etc. due to security reasons. In any case, the updated information of the location of the ship does not provide the customer with the answer to the date on which his container will arrive at the port of destination, since during the journey the ship will make or omit other stops, and these may result in the trip being of a different duration than the forecasts. In this scenario, shipping companies try to provide the most update information to the customer mainly via email or website.

To complete the understanding of the current situation, we must mention another problem related to the monitoring of cargo status. Once cargo is loaded on the container no information on its status is available. During the journey the container can suffer multiple alterations: any movement during stowage that alters the correct distribution of the goods, suffer a blow, important changes in temperature and humidity, water leaks, etc. Depending on the type of cargo, if any of the aforementioned incidents happen, it may be that at its destination the goods will no longer be marketable. If the customer knew this in advance, they would have more time to adopt a solution to the problem. Knowing what, when and where an incident has happened not only helps to look for alternatives, but also could be of a great help in solving legal and insurance problems and, in the long term, to predict possible events.

IN COMING SITUATION

As we mentioned at the beginning of the article, logistics is moving towards digitalization, which is also joined by the automation of many processes, the use of artificial intelligence to assess real-time decision-making, the use of IoT to get real-time data and monitoring, etc.

What role does E2E tracking take in this development?

The most innovative future scenarios are committed to a logistics chain in which the means of transport are not predefined and it is in each transport node where the next step is decided, according to real time data, depending on the capacity, time, costs, emissions, etc. For this it is necessary that each intermodal point is an intelligent node that, supported by Artificial Intelligence, can help decision making. In order to achieve this, it is necessary to create a virtual simulation capable of studying the different alternatives and choosing the next step taking into account environmental and economic factors, transit time and road capacity.

For this future scenario, tracking and monitoring devices in shipping containers will make them to become “smart” containers. For intelligent and automatic scenario to be possible, it is necessary that the containers are equipped with IoT sensors in order to know their location, traceability, the status of the cargo (position, door opening detection, vibrations and bumps, temperature, humidity, etc.). Data received in real-time, together with stored historical data, can be used to feed artificial intelligence and help it learn for future situations.

In addition, the use of blockchain technology for integrated and trustable data sharing can be used to store the collected real-time data making it available to actors involved in the supply chain to feed their own processes thought interoperable blockchains. Nowadays a trade operation, whether being import or export, requires coordination of complex supply chains through multimodal corridors ending to hold multiple interactions and transactions with different stakeholders. For years to come, the development of Blockchain solutions for maritime transport that includes all the agents involved in an import/export trade operation, can be very advantageous in terms of reducing the multiple interactions and redundant data transactions between all actors while keeping trustable common records of each event. Since the use of blockchain technology will help to enhance the information flow between all agents, optimizing the operations time and avoiding errors and duplication, that will result in a reduction of the costs and time of the processes for all the actors involved.

INGENIOUS DEVELOPMENT

The goal of iNGENIOUS is to take some steps towards this future situation. In one of the Use Cases in the project, we focus on the monitoring of intermodal transport through the Internet of Things and satellites.

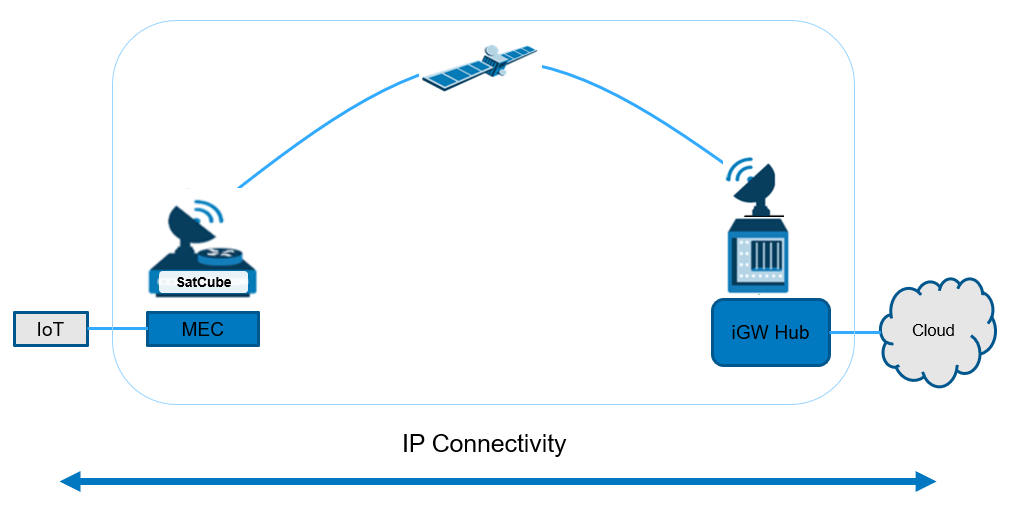

This use case aims at providing E2E asset tracking via satellite backhaul from the IoT RAN to the corresponding data/control center, enabling real-time/periodic monitoring predetermined parameters (temperature, humidity, accelerometer, etc.) of shipping containers when they are sailing on the sea, while terrestrial IoT connectivity is provided when the ship approaches the port. To enable ubiquitous coverage, IoT tracking devices will be installed on the shipping containers transported by ships and trucks on both segments. The end-to-end intermodal asset tracking would allow shipment information to be ubiquitously available across all connected platforms and interested parties in real-time.

With the aim of testing the developments of the UC, a real DEMO of a transport from Valencia to Piraeus will be carried out, combining the transport by truck in Valencia and the vessel route Valencia-Piraeus-Valencia.

In this Use Case, a set of IoT Sensors has been designed and provided to obtain information about container temperature, humidity, movement, vibration, and gate opening events. These sensors will be integrated together with LoRa and NB-IoT communication modules and then installed on the shipping container to monitor cargo conditions and container status when terrestrial and maritime transportation is performed. This information is emitted through the sensor and received by the gateway. The ideal scenario is that the gateway is located in the ship and can obtain data from all sensors in real time; one possible alternative during the DEMO is that the information stored by the sensors is received by the gateway once the ship arrives at each port.

Commercial GSM and NB-IoT coverage will be available to perform IoT tracking tests inside the port facilities. IoT tracking devices will use this coverage to report the tracking measurements gathered in tracking tests.

A 20 feet dry container will be purchased for the demonstration. The container will be sensorised and transported in terrestrial and maritime segments as part of the round trip from Valencia to Piraeus. Ship with AIS for navigation data exchange and VHF radio connection for exchange when the ship is approaching the port will be used for performing UC demonstration. The route from Valencia to Piraeus is served by COSCO AEM2 and BSM lines, so the container will be loaded on a 14000 or a 3000 TEUs vessel, respectively.

The demonstration activities will start on the depot facility in the port of Valencia where the integration of sensors will be performed. Then iNGENIOUS container will be loaded on COSCO terminal at the port of Valencia and discharged as part of the trip to Piraeus.

The shipping container will be loaded on the ship and transported from the port of Valencia to the port of Piraeus and vice versa. During the trip, depending on the service level required by the owner of the container and the supply chain associated, the heterogeneous IoT devices installed on the container send regular status updates, and these messages will be aggregated, stored and processed by a Smart IoT Gateway installed on the bridge or IT room of the ship.

To enable ubiquitous coverage, when the ship arrives at the port of Valencia, the container will be discharged from the vessel and will be loaded on a truck during the demonstration. Then, the truck will leave the port of Valencia and transported to inland.

The results of the use case will be shown in a project dashboard to visualize all the sensor data, temperature, humidity, movement, vibration, and gate opening events and show it to the users with an attractive and intuitive design.