Technology Insight – Inter-Model Asset Tracking Via IoT and Satellite

by SES TECHCOM

Introduction

Currently, no real-time data can be collected and exchanged along the whole supply chain. Ships are equipped with legacy communication networks allowing to exchange information with port terminals when ship is docking, but not when it is sailing. No sensors are installed in containers to monitor and collect real-time data on cargo location and conditions and container safety.

Thus, this use case aims at providing end-to-end (E2E) asset tracking via satellite backhaul from the internet of things (IoT) radio access network (RAN) to the corresponding data/control centre, enabling real-time periodic monitoring of predetermined parameters (temperature, humidity, movement, bumps, etc.) of shipping containers when they are sailing on the sea, while terrestrial IoT connectivity is provided when the ship approaches the port. To enable the ubiquitous coverage, IoT tracking devices will be installed on the shipping containers transported by ships and trucks on both segments. The end-to-end intermodal asset tracking would allow shipment information to be ubiquitously available across all connected platforms and interested parties in real-time. Data analytics on this rich and timely data would further allow supply chain players to achieve operational excellence, major reductions in operational uncertainties, and increased revenues.

Architecture

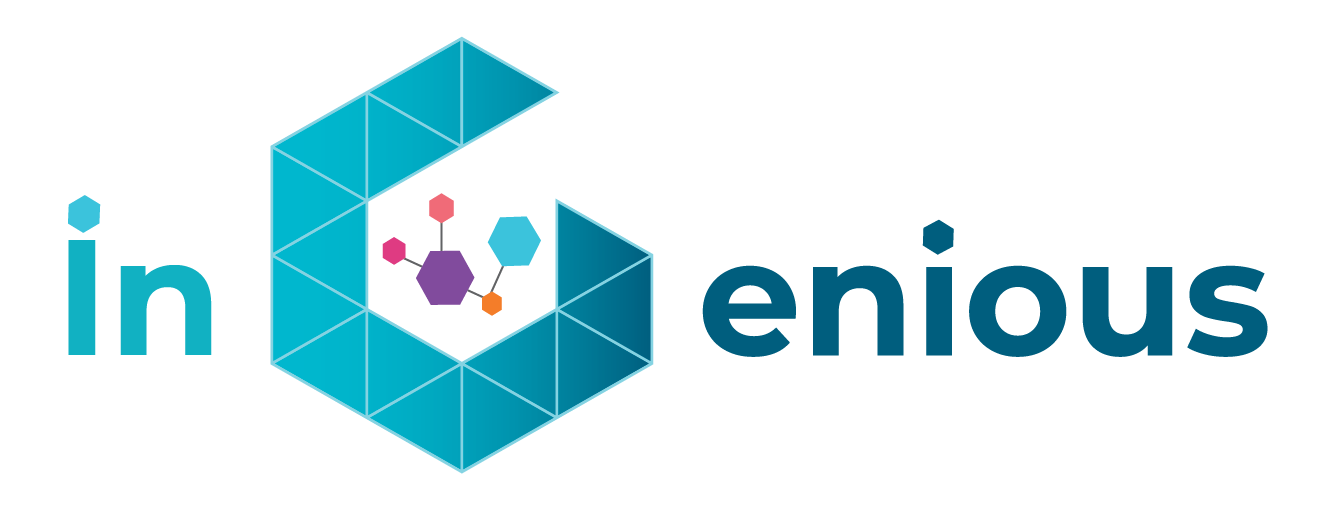

The architecture of this iNGENIOUS use case is depicted in Figure 1 and the following activities need to be performed:

- A 20 foot shipping container will be equipped with a certain number of heterogeneous IoT devices able to monitor the internal environment of the container (accelerometer, temperature, humidity) as well as to detect critical events (physical shocks, door opening).

- The shipping container will be loaded on a truck and will be transported from the inland to the port of origin.

- During the trip, the heterogeneous IoT devices will send regular status updates, the Smart IoT gateway (GW) on the truck will gather and process the data and the connectivity with the IoT cloud/Data centre will be obtained through terrestrial access network.

- The shipping container will be discharged from the truck and it will be loaded on a ship.

- The shipping container will be transported from the port of origin to the port of destination and vice versa. During the trip, depending on the service level required by the container owner and the supply chain associated, heterogeneous IoT devices will send regular updates (frequency could go from one message per hour to one message per day).

- The messages from the heterogeneous IoT devices will be aggregated by a Smart IoT Gateway installed on the bridge or IT room of the ship.

- When the ship is travelling on the sea the data will be sent to the IoT cloud/data centre through satellite backhaul (a satellite terminal will be installed on the ship). The baseline space segment to be used corresponds to the SES’s GEO satellite fleet, which will provide seamless connectivity between the ship satellite terminal and the innovative 3GPP compliant hub platform located at the SES teleport in Betzdorf, Luxembourg.

- When the ship arrives at the first port, the data will be sent to the IoT cloud/Data centre through satellite backhaul or terrestrial access network.

- Then, the shipping container will be discharged from the ship and loaded on a truck.

- The truck will leave from the first port and it will transport the shipping container. During the trip, the heterogeneous IoT devices send regular status update, the Smart IoT GW on the truck gathers and processes the data and the connectivity with the IoT cloud/Data centre is obtained through terrestrial access network.

Smart IoT Gateway

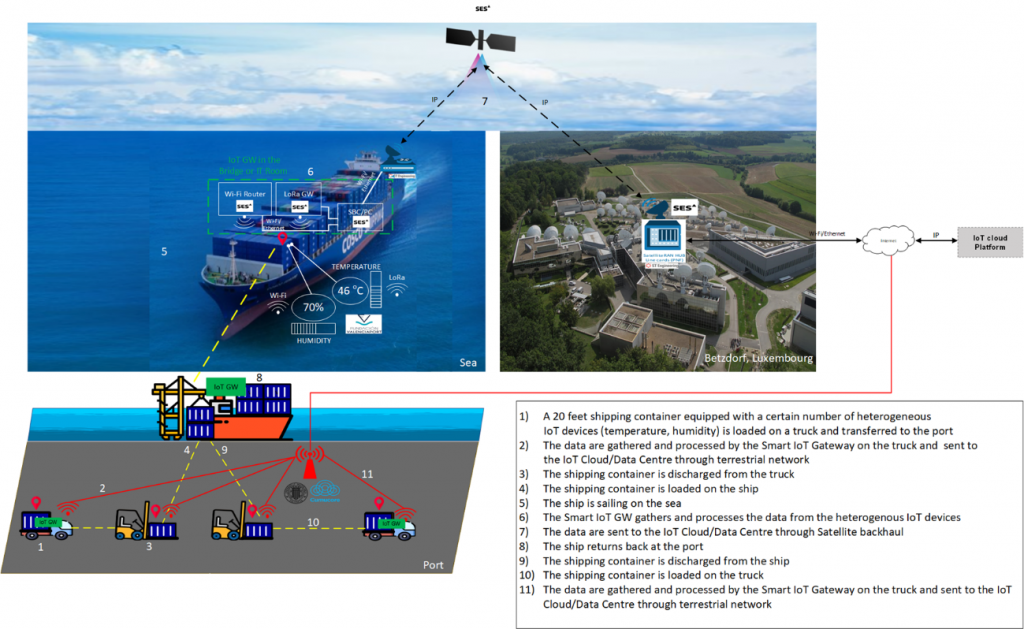

The Smart IoT GW is a very important element of this use Case. The Smart IoT GW is the system element responsible for the appropriate routing and sorting of sensor data, coming from one or more sensor networks, to higher layer data consolidation services and machine-to-machine (M2M) platforms. For performing these operations, the Smart IoT GW is able to interconnect multiple physical interfaces, as well as extracting and transforming messages as data traverses from one side to the other.

Taking the OSI model as a reference, the Smart IoT GW will expose several physical and data-link interfaces to receive sensor data. Sensors can send messages to the Smart IoT GW either wirelessly (with technologies such as IEEE 802.11, LoRa, or Sigfox), or directly connected to the device (via Ethernet, I2C, or SPI) as shown in Figure 2. The Smart IoT GW will be smart enough to manage the routing and direct the received messages to the right output interface in the right timing. Several factors will be taken in consideration in this operation:

- Context such as the current geographical location of the Smart IoT GW or its situation relative to potential recipients of messages

- Message prioritization due to urgent messages that need to be forwarded immediately over other messages that can be grouped together for channel usage optimization

- Channel availability like in cases where constrained communications impose a specific interface linked to a channel, such as a satellite link in situations where the Smart IoT GW is deployed on a ship sailing far away from the coast. In a diametrically opposed scenario, the ship would be moored in the port and the Smart IoT GW would favor a link established by 4G LTE taking advantage of a nearby mobile network station.

Physical interfaces are added to the Smart IoT GW as plug-in modules, that allow to abstract most of the device functionality from the number and type of the interfaces installed in the Smart IoT GW.

Operational, Business, Societal and Environmental Outcomes

The container tracking is an essential part of the supply chain and logistics to make them more efficient. By monitoring and tracking seamlessly the container in near real-time, it allows to provide all the supply chain players and stakeholders a full traceability and to optimize the transport and the storage of containerized goods. Any event related to a container is quickly notified and is allowing efficient analytics as well as taking related decision such as new sourcing plans if needed.

By tracking and tracing the cargo, the operator will monitor the asset movement, will record the actual routes, transit times, stationing in the facilities and congestions for every transport mode. By analysing the transit performance, the operator will take informed decisions by choosing preferred routes, carriers or even modes of transport.

By monitoring temperature, humidity, accelerometers, and even simple contact sensors the operator will assess additional states applicable for various goods. Temperature and humidity are relevant for perishable goods and abnormal variations in the values, and they will indicate the immediate need for maintenance in order to avoid the loss of goods. Furthermore, the accelerometer output will provide real-time indication about the integrity of the goods and abnormal variations may trigger subsequent inquiries which may conclude that an accident occurred, and intervention is required.

Continuous contact sensors data may certify that the goods are transported securely in their containers and nobody attempted an unauthorized access. In eventuality of a door alarm the operator will alert appointed security entities to counteract a potential illegal action. Moreover, the IoT interoperability will enable the federation of different IoT platforms within heterogeneous domains, overcoming the compatibility issues between both standard and non-standard, proprietary, and custom M2M solutions. Also, it will enable the better exploitation

Summary

In summary, this iNGENIOUS use case will focus on the following innovation areas:

- Providing E2E intermodal asset tracking via satellite and IoT technologies;

- Optimising real-time data interchange along the whole supply chain, improving customer satisfaction and increasing transparency and collaboration;

- Developing a Smart IoT Gateway allowing interoperability between heterogeneous IoT devices.